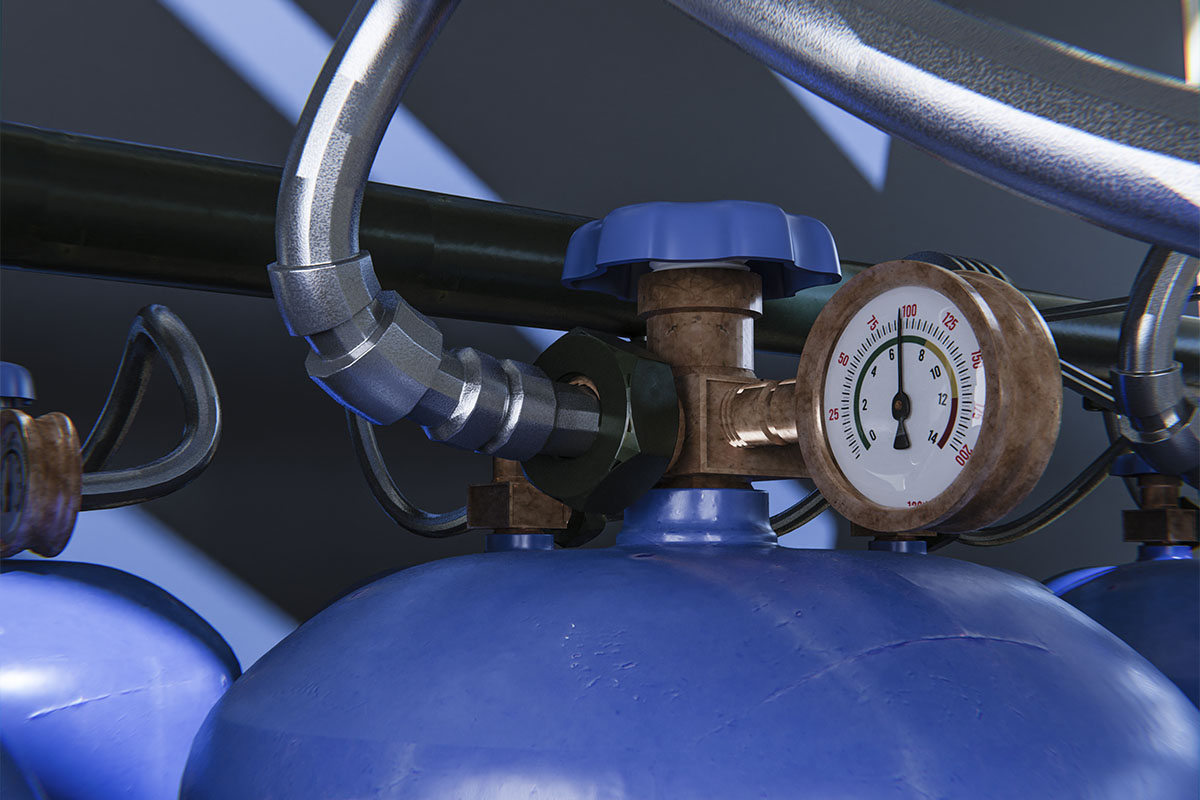

A pressure transducer is capable of accurately measuring pressure. It converts applied pressure into an electric signal and can be classified as an active or passive pressure measurement device.

Various designs of pressure transducers are available depending on whether absolute or relative pressure measurements are required. Flush Ceramic Sensor

Originally developed to measure minimal pressure changes, pressure transducers gained widespread commercial adoption in the 1960s and 70s by introducing thin film, silicon, and quartz-based devices. This made them a popular choice for measuring both low and high pressures.1

A pressure transducer comprises two main components: a pressure-sensitive device and a transduction element that converts device changes into an electrical signal.

Multiple designs exist for pressure transducers, utilizing methods such as strain gauge displacement or membrane movement. The design choice depends on the pressure ranges that need to be measured.

Pressure transducers measure static or dynamic pressures, depending on whether the measured object is stationary or subject to an applied force.2

Piezoresistive strain gauges are commonly employed to measure static pressures.

These gauges are attached to a diaphragm that deforms under pressure, leading to a change in resistance which provides a measurable electric signal. This change in resistance is converted into a measurable voltage using circuit configuration.

In the case of high-compact pressure transducers, a microelectrochemical system (MEMS) device is used.

MEMS-based pressure transducers operate on similar principles as their larger counterparts, where deformation in the sensing medium generates an electrical signal. However, MEMS devices are much smaller and more responsive to even minor pressure changes.3

For remote applications like environmental monitoring in unmanned aerial vehicles (UAVs), MEMS sensors offer advantages such as low power consumption and lightweight construction.4

Image Credit: Merit Sensor

The S-Series, developed by Merit Sensor, is a remarkable sensor development and manufacturing achievement. These MEMS silicon pressure dies utilize a thin, flexible diaphragm as their sensing medium.

The diaphragm's deflection, caused by pressure, alters the resistance between two plates. This alteration can be converted into an electrical signal to provide pressure readings.

To deliver unparalleled performance, accuracy, and reliability in pressure sensing, the S-Series leverages Merit Sensor's cutting-edge MeritUltra™ technology. These dies are designed to operate effectively across various pressures, from 5 to 300 psi, making them suitable for diverse applications.

By incorporating the MeritUltra™ technology, the S-Series dies offer an impressive temperature operating range of 40 °C to 150 °C without compromising performance.

The exceptional accuracy of the S-Series dies enables designers to achieve accuracies better than 0.1% of the full scale, making them suitable for even the most demanding high-precision applications. The S-Series is available with and without glass.

Image Credit: Merit Sensor

High-quality calibration is a critical factor in pressure sensing. Precisely translating the movement of the diaphragm into meaningful pressure values necessitates a thorough characterization of the resistance change in response to applied pressure.

To ensure this, every S-Series die undergoes electrical testing at the wafer level when constructed at Merit Sensor Systems' wafer fab in South Jordan, Utah, USA. The dies can be packaged by mounting them onto a circuit board and incorporating the necessary signal amplification electronics.

Extensive and rigorous testing and calibration procedures are employed, ensuring the dies are ready to provide reliable measurements immediately.

The S-Series dies' robustness, reliability, and outstanding technical performance make them the preferred choice for many engineers when building pressure transducers.

Their compatibility with a wide range of environmental conditions, excellent sensitivity, and compact footprint make them ideal for numerous applications, including industrial, automotive, and medical sectors, where components must meet additional regulatory requirements regarding reliability and performance.

Whether clients require pressure transducers for aerospace, automotive, medical device engineering, or any other application, reaching out to Merit Sensor Systems will enable them to explore the benefits of incorporating its state-of-the-art pressure dies into their devices, leading to improved reliability and performance.

With the backing and expert support of the experienced professional teams at Merit Sensor, the client receives high measurement reliability, comprehensive pre-and post-sales support, and expert technical advice.

This information has been sourced, reviewed and adapted from materials provided by Merit Sensor.

For more information on this source, please visit Merit Sensor.

Please use one of the following formats to cite this article in your essay, paper or report:

Merit Sensor. (2023, July 26). Enhancing Pressure Transducer Performance with the S-Series Die. AZoM. Retrieved on January 22, 2024 from https://www.azom.com/article.aspx?ArticleID=22829.

Merit Sensor. "Enhancing Pressure Transducer Performance with the S-Series Die". AZoM. 22 January 2024. <https://www.azom.com/article.aspx?ArticleID=22829>.

Merit Sensor. "Enhancing Pressure Transducer Performance with the S-Series Die". AZoM. https://www.azom.com/article.aspx?ArticleID=22829. (accessed January 22, 2024).

Merit Sensor. 2023. Enhancing Pressure Transducer Performance with the S-Series Die. AZoM, viewed 22 January 2024, https://www.azom.com/article.aspx?ArticleID=22829.

Do you have a question you'd like to ask regarding this article?

AZoM.com - An AZoNetwork Site

Hydrogen Cooled Generator Sensor Owned and operated by AZoNetwork, © 2000-2024