With dozens of options in HVAC tapes, determining which one is right for your job is critical. It’s important to consider factors like UL Listings, the type of surface the tape must adhere to, and whether the tape has the strength and longevity to hold throughout the system’s life span.

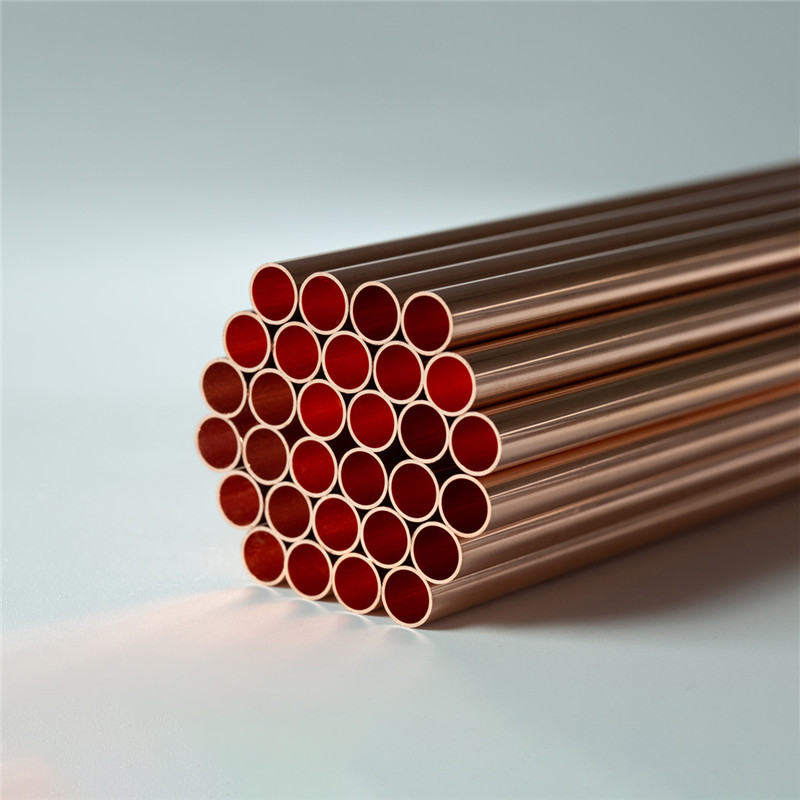

The first consideration in tape selection is backing. Most HVAC applications necessitate a tape with a foil or film backing, although there are some cloth duct tapes which are robust enough to be used in HVAC applications. Both are designed to provide full system closure – meaning the system is free of air leaks – and are durable and robust enough for the life of the system. Bending 10mm Copper Pipe

Film tapes allow for maximum surface contact with the adhesive by easily conforming to rough and uneven surfaces, which makes them an excellent option for sealing flexible duct and reflective insulation.

However, because of their robust construction and durability, foil tapes are the most common for HVAC jobs. These tapes are frequently found on jobs that require UL Listings due to safety and code compliance. UL Listed foil tapes are used to seal air duct and air connectors and have been stringently tested for flame resistance, mold growth and humidity, static load, impact, pressure, collapse, tension and more.

There are two main types of UL Listed tapes commonly used in HVAC applications: UL 181A-P Listed and UL 181B-FX Listed.

UL 181A-P is used to seam, seal and join rigid fiberglass duct board, flexible air duct and sheet metal. It’s made from aluminum or aluminum alloy foil and must have a minimum width of 2.5 inches. Due to the aggressive nature of acrylic adhesives, most UL 181A-P foil tapes have a release liner. Ideal for use in a variety of temperatures, this tape is strong enough to withstand the vast thermal cycles of any HVAC system.

UL 181B-FX may be used only on Class 1 Flex duct. In construction, these tapes must be foil, film or cloth with a minimum width of 1.88 inches; the primary function is to seam, seal and join HVAC materials. Some UL 181B-FX tapes can be substituted for traditional paint-on mastic.

No matter which HVAC tape is chosen for the project, when it receives a UL Listing, it guarantees that the HVAC tape has proper adhesion and exceptional shear strength to stay in place for the life of the system.

This is especially important when installing components like plenum, which is responsible for sending heated or cooled air throughout the length of a building’s ductwork. UL Listed foil tape that is approved for sheet metal and performs well in a wide range of temperatures will ensure a completely closed system that will withstand the test of time.

Understanding UL Listings and which tape provides the right adhesive for the material on the jobsite is crucial. However, by looking at backings and knowing more about safety codes, it’s fairly easy to determine.

You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days.

Copyright ©2024. All Rights Reserved BNP Media.

Lwc Copper Tube Design, CMS, Hosting & Web Development :: ePublishing