For full functionality of this site it is necessary to enable JavaScript. Here are the instructions how to enable JavaScript in your web browser.

Save to read list Published by David Bizley, Editor World Cement, Wednesday, 12 July 2023 10:30 Thermal Power Plant Carbon Brush

Mathis Menzel, Menzel Elektromotoren, advises on good practices and potential pitfalls for brush-lifting mechanisms on slip ring motors.

Slip ring motors offer many advantages for heavy-duty applications, but they require regular cleaning and maintenance. Brush lifting may be advisable in some cases as a way to decrease brush wear and minimise service costs: slip ring motors can be fitted with short-circuiting and brush-lifting devices in high-power applications with long run times and where the costs for regular brush exchange outweigh the investment in this technology. Few motor builders offer this option. Menzel Elektromotoren has now added brush lifting to its standard portfolio. The German motor manufacturer has the advantage of being a one-stop shop for the consultation, configuration, construction, and commissioning of entire motor systems with a brush-lifting device.

The company offers several own-brand motor series and is also specialised in the customisation and identical reproduction of existing motors. Various motor versions up to 15 MW are kept permanently in stock and are adapted at short notice for a wide variety of applications and locations. The overall output range goes up to and beyond 20 MW. Furthermore, Menzel offers comprehensive testing services for electric motors, generators, transformer–converter–motor systems, gearboxes, and frequency converters, with idle tests up to 10 MW, load tests up to 1.8 MW, and bifrequency heating tests up to 5 MW. After decades of working in the cement industry, the engineers know their customers’ requirements and expectations very well and provide solutions quickly and flexibly, even for unusual demands. In its own motor series, the company follows the modularity principle, enabling economic, flexible adaptations to different application requirements.

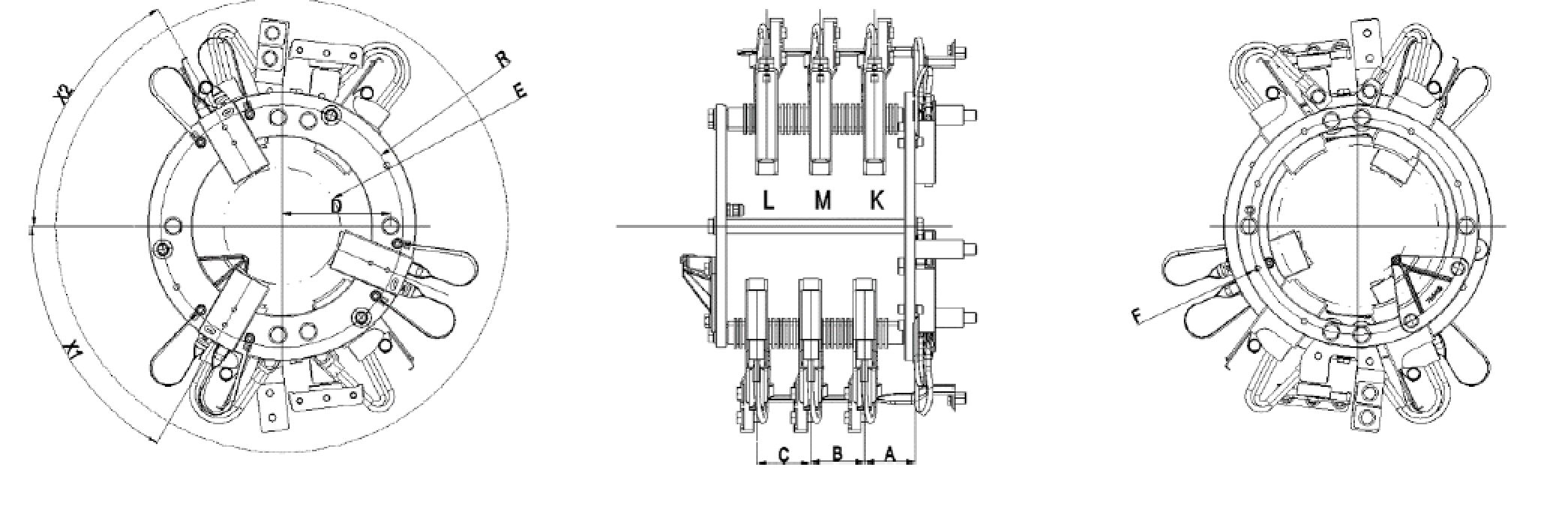

One of the rarer customer requests is for a slip ring motor with brush lifting. Slip ring motors enable start-up with high starting torques and low inrush currents. For this purpose, starting resistors are switched on via carbon brushes that slide over the slip rings, thus establishing a contact to the rotor windings. After motor start-up, the external resistors are switched off. Typically, the brushes just stay in place. Combining conductive material such as copper with compressed carbon dust, the brushes are continuously worn down and carbon dust is released through the sliding contact. In order to minimise brush wear and maintenance requirements, the rotor windings can be short-circuited and the brushes lifted from the slip rings after starting and after the motor has reached the nominal speed. The motor will then run efficiently at a single speed, and the brushes will only be required again for the next motor start. The brushes can be smaller and will last much longer, often the entire motor lifespan. The slip ring compartments will need less frequent cleaning. As an added advantage, brush lifting eliminates contact resistances and friction, resulting in a slight efficiency boost. Finally, after motor standstill, the brushes are returned to their starting position.

Applications include but are not limited to mills, crushers, conveyors, fans, and pumps. Slip ring motors are typically used for high-power applications with continuous operation (duty type S1) and slow starting that require high starting torques and high nominal torques. In contrast, squirrel-cage motors (without any need for motor brushes) are more common in variable-speed applications and are the preferred choice in most applications today. However, there is still a stable demand for slip ring motors that, in addition to their good performance properties and rugged design, can withstand voltage fluctuations and can therefore be used without problems in regions where grid stability cannot be relied upon. On the downside, there is constant wear on the motor brushes such that they need to be exchanged at regular intervals, which has to be integrated in the plant’s service regimen.

Enjoyed what you've read so far? Read the full article and the rest of the July issue of World Cement by registering today for free!

Read the article online at: https://www.worldcement.com/special-reports/12072023/minimising-motor-maintenance/

Join World Cement in Lisbon, 10 – 13 March 2024, for our first in-person conference and exhibition: EnviroTech.

This exclusive knowledge and networking event will bring together cement producers, industry leaders, technical experts, analysts, and other stakeholders to discuss the latest technologies, processes, and policies being deployed at the forefront of the cement industry’s efforts to reduce its environmental footprint.

Get your advance tickets NOW »

Nathan Schindler, Evonik Corporation, describes how implementing a high-performance fibre material can help cement plants avoid air pollution and meet EPA standards.

Embed article link: (copy the HTML code below):

This content is available to registered readers of our magazine only. Please sign in or register for free.

Register for free » Get started now for absolutely FREE, no credit card required.

Already a member? Sign in here

Ready to revolutionise the cement industry?

Join World Cement in Lisbon, 10 – 13 March 2024, for our first in-person conference and exhibition:

This exclusive knowledge and networking event will bring together cement producers, industry leaders, technical experts, analysts, and other stakeholders to discuss the latest technologies, processes, and policies being deployed at the forefront of the cement industry’s efforts to reduce its environmental footprint.

Get your advance tickets NOW

Affordable Slip Ring Copyright © 2023 Palladian Publications Ltd. All rights reserved | Tel: +44 (0)1252 718 999 | Email: enquiries@worldcement.com