As someone incapable of properly installing a screen cover onto a phone, I knew that applying XPEL Paint Protection Film (PPF) — a clear, self-healing urethane that clings onto a car’s paint and protects it for a warrantied 10 years — to a car would be challenging. What I didn’t expect was just how challenging, especially since the vehicle I planned to beat the crud out of off-road in order to test the PPF is such a basic, flat-sided Jeep Wrangler YJ. “Surely something this simple will be easy to wrap PPF around,” I thought. Here’s why I was wrong.

Thus far, The Autopian has announced its partnership with leading Paint Protection Film company XPEL, written about how unbelievably beautiful my cheap Jeep Wrangler YJ now looks since receiving PPF, and discussed why PPF makes so much sense for off-road vehicles in the first place. You should read all of those, especially that last one, because this partnership really is based on a knowledge that XPEL not only makes a great product, but also that it’s something that many car enthusiasts really would benefit from. Plotting Machine

A few months back, I had my Jeep Wrangler YJ done up in the finest, thickest (10 mil, so ten times 0.001 inches = 0.01 inches) PPF that XPEL offers, called XPEL Ultimate Plus 10. The idea is that I’m going to take my Jeep off-roading through thick brush and nasty muck, and see how much more comfortable I am subjecting my paint to the elements knowing that I’ve got PPF there as protection. And ultimately, I’m going to keep track of how nice my white paint remains after many, many off-road excursions.

As shown in our YouTube video, the XPEL PPF application all went down at 405 Motoring, a premium shop in Inglewood that does detailing on some of the most most high-end machines in existence, including Lebron James’ Bronco:

A post shared by XPEL Los Angeles | PPF, Tint, Vinyl, Ceramic, Dry Ice ++ (@405motoring)

A post shared by ???? (@kingjames)

That Lebron and all the owners of these high end cars put XPEL on their vehicles says a lot, but again, it’s just confirming what I’ve already heard from so many car enthusiasts: the product is legit.

Before arriving at 405, I washed a bunch of mud off my Jeep YJ, though I’ll admit that I could have done a better job. You see, applying PPF requires a vehicle to be spotless. Any dirt that gets caught on the film can make application an absolute bear. Luckily, 405 has its own car wash inside the building. It’s honestly the nicest one I’ve ever seen, with a snazzy looking rotating arm and tiled flooring:

Once the Jeep got cleaned, 405 Motoring did a lot of work on the paint, because even though the Jeep had been repainted, it was by a guy in his garage. Remember, I only paid $7,800 for this 200,000 mile Jeep (the PPF job, 405 Motoring told me, cost about as much as my Jeep), and by the time I sold the doors and roof, I was really only in it about $6,500. It was a bargain, and the paint didn’t exactly shine, though 405 motoring fixed that with some serious detailing work. Once the Jeep was squeaky clean and the paint was shining, it entered the “Clean Room,” which you can see has a giant XPEL logo on it.

The clean room is exactly what you think it is: It’s a controlled environment meant to minimize dust, dirt, or grime from affecting the PPF (and wrap) installation process. Check it out:

A post shared by The Autopian (@theautopian)

Even after my Jeep made its way into the clean room, a tarp had to be put over the filthy engine to prevent contamination, and even more cleaning had to be done, as this Jeep was old, and had seen many, many days off-road:

In addition, a bunch of trim had to be removed, as the beauty of properly-applied XPEL is that its edges are often hidden under trim and out of sight. Unfortunately, 405 Motoring’s trim-removal guy was out, but, given that I’d pretty much installed the trim myself a few weeks prior, I made quick work of it:

A post shared by David Tracy (@davidntracy)

Doing all this work was Johnny, a PPF installation master:

Here you can see him holding some baby shampoo, which is mixed with water to create what’s called a “slip solution,” which is sprayed onto the film prior to application so that the film can “float” on painted panels as installers position it and squeeze out the solution. More on all that later.

For now, I had to ask Johnny how exactly his team figured out what size to make the film. He told me that, unfortunately, for my YJ, they had to custom-cut each piece, but this isn’t the case for most cars, as XPEL has a sweet program called “DAP.”

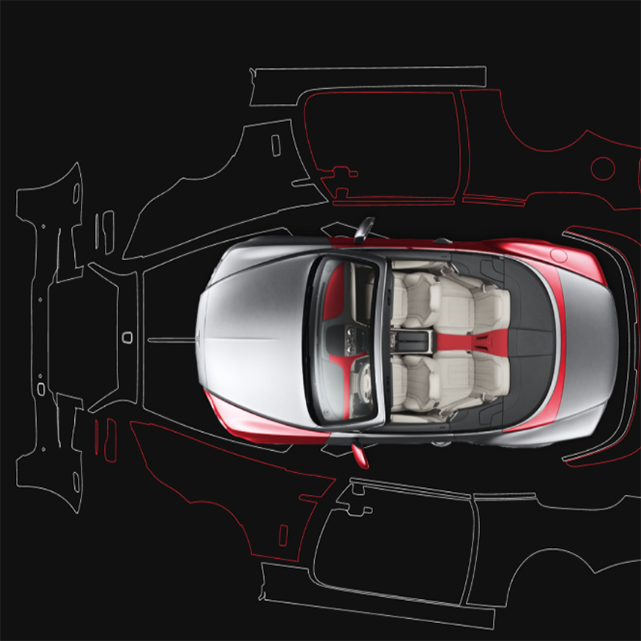

I won’t get too far into “DAP,” since XPEL experts later showed me how it works at SEMA and I’ll share that soon, but the short of it is that you can pull up a car in a drop-down menu, and literally print out the exact-size film for each panel. You can see two fenders and a hood in the image above, oriented in such a way that they’re all able to be plotted on a single piece of film.

405 Motoring’s social media guru Aalias Williams showed me the plotter (on the left side of the image below), as well as the computer they use DAP on, and a bunch of rolls of film:

It’s hard to tell in this image, but on this one piece of film, multiple pieces of PPF have been precisely cut by the plotter so that they can be removed individually and installed onto each panel:

Of course, there was no such luck with my Jeep YJ; it’s so old and its value is so low that I bet I’m one of few people who have ever had a YJ PPF’d. As such, it was not included on DAP, meaning Johnny had to custom-cut each piece from bulk-material (I kept noticing him replacing razor blades, only to learn from him that the film was actually dulling the blade!). Typically, he’d slap the correctly-shaped film onto the special board shown below, and then moisten it, remove the film from its backing sheet, and then install the film, but instead, Johnny sized up a big piece of rectangular bulk, and put it up on the board.

You can see him moistening it now as. he prepares to remove it from its backing sheet:

Here’s that removal process:

Johnny was very careful to make sure he was able to spray all of the film:

He then sprayed down the side of my Jeep:

And from there began the intricate “transfer” process, which in this case required a second set of hands. Basically, the transfer process means taking the film from the board, and gently placing it down onto the vehicle:

Placing the film exactly right isn’t a huge deal, since the slip solution allows the urethane to float a bit, but there are other, tackier solutions that tend to “set” things in place, and as Johnny squeegeed the solution out, the film began to take hold:

It’s an incredibly intricate process, especially when you’re doing custom-fit film like Johnny was. But the difficulty of this job goes beyond the film having to be custom fit; the Jeep Wrangler YJ is actually not an easy vehicle to apply film to, and that’s something that I wasn’t expecting. It’s such a simple design, with flat sides, and a basic, rounded hood. If you’d asked me before this experience how hard I thought applying film to a YJ would be relative to other cars, I’d have said “Probably a three on a scale of one to 10.” But that’s just wrong.

The reality is that modern aerodynamic cars lend themselves to PPF installation so much more than my old Jeep does. Take this Tesla Model Y for example:

Just looking at it, you can imagine how easy it would be to put film on those panels. Sure, there are a few character lines that break up the “flowing” nature of the sheetmetal, and there’s that little feature on the fender, but this thing would be a very simple PPF install even if it weren’t in DAP (and it is). Meanwhile, my Johnny had to deal with this on my YJ:

See that stamped Jeep emblem in my tub? It was a bubble-trapping nightmare. Johnny showed me this cool trick where he uses a syringe to suck out the air trapped next to the letters, then he presses down with his thumb to “set” the film:

Johnny also had all these protrusions to worry about, like the exposed door hinges, which he had to very delicately cut around.

Watch as he uses tweezers to remove small pieces of PPF as he cuts it as close to the bracket as possible!:

All the seams between the panels aren’t ideal, either, as they require Johnny to cut the film between them in exactly the right way so that the edge of the film remains as invisible as possible. All the while, he has to make sure that he’s cutting film and not paint, and that itself is a true art:

Johnny even showed me a trick for removing dirt that makes its way onto the film: He uses the back side of masking tape to scoop the crud out:

Throughout the job, Johnny was constantly applying slip solution, squeegeeing, adding solution, cleaning, squeegeeing, cutting, pressing with his thumb, adding solution, and on and on.

It’s a true art, and the way Johnny precisely cut each piece of film, folding many of them so that you never see the edge (I can’t even see the edge of the PPF on my doors and the hood) is just masterful:

But nothing was so masterful as how Johnny applied PPF to the YJ’s rather complex grille, a surface that I didn’t even think was going to receive PPF treatment. He began by placing a roughly-sized rectangular piece of slip solution-soaked PPF onto the grille:

Then, after placing the piece where he liked it, Johnny squeezed out a bunch of solution:

From there, he began trimming:

The most impressive part was the grille slots, where the shape of Johnny’s cut was based on the shape of the inner walls of the grille slats that he would be folding the PPF onto:

The results are just amazing:

Not only has the car been detailed, but the PPF adds this almost candy-like clearcoat effect, making the thing just pop. Aside from that lovely effect, it’s hard to tell that there’s any coating on there at all — it’s all just so well hidden and tucked and folded. Like I said, masterful:

I just took my Jeep off-roading this past weekend, and believe me when I say: I beat the crap out of this Jeep. And you know what? I wasn’t worried at all about that gorgeous paint getting scraped up:

And that’s a good thing, as I had other things to worry about:

This stuff was a bit of a hype in my area half a dozen years ago but it died out as quickly as it gained popularity ;

the film is less hard than your paint. Stones and grit and especially a scuff WILL destroy the film and since the film ages ; you cannot easily replace just one piece or better said ; no installer is interested in doing your front left fender for a fraction of the cost of the whole car and even if you do ; it will just look slightly different to the point that you will get annoyed.

Most ppl I know change cars more often than once per 10 years, so in the end they didn’t car anymore about a bit of paint damage.

If you have a cheap car ; the $6000+ job is a non-starter and if you have a Very Expensive car then a total respray would be also no problem since you have A Lot Of Money in the first place.

So that friend of mine who PPFd his Infinity looked like a douche in the end ; you can see the PPF film from a mile away and it made him look like a car-zealot-douchebag, worried about every single itty bitty little scratch on his totally not very expensive car.

Johnny‘s job looks so damn satisfying. I’d love to try it, just as a hobby. Spectacular work!

10 mil, we laminate drawings with that thickness at work. At least when it’s fused back on itself, it’s some crazy heavy stuff.

Really surprised that the spare tire wasn’t removed first?

If you’re gonna do partner posts, this is the way. Who knew it’s possible to plug for your sponsors and be interesting at the same time? There’s even a dramatic twist at the end, fer cripes sake.

I had PPF applied to all my recent cars but not the ones I bought before PPF got good enough. Would like to know more about how much paint correction they needed to do on such an old car like yours.

Sooo, instead of worrying about damaging the paint, you now have to worry about damaging film, film that cost more than the Jeep did…

That paint sure does look good though.

That film has a 10 year-warranty. I ain’t worried about it! It heals itself!

You could take it to Moab and try it out there, possibly around easter time.

that type of stuff was hard enough to put on my phone screen. same process. Johnny is a master.

Same, it’s a pain in the rear!

I knew a very meticulous fella once that read me into his procedure. He would run a hot shower in his apt bathroom to achieve the desired humidity and suppress dust, and apply it to the device that had also been in the bathroom warming up so there wasn’t condensation going from cold and dry to hot and wet.

Great article, timely too. My car gets a front ppf and window tint using xpel products next week so it was great to see exactly what’s going to happen.

Can they wrap David in freeze protection film? All I can think about today is him freezing his heinie off. Stay warm!

1 mil = .001 in 10 mil = .01 in = .010 in = thickness of the film as described in the post 1 mil is closer to Saran Wrap

Still though, 10 mil is honkin thick. I’ve got a hole in my roof patched with 10 mil plastic for like, more than a year now. I’ll fix it as soon as [impossible condition is met, e.g. “the Z4 is running well *and* has AC”]

I’m a little surprised they’re wearing street clothes and not Tyvek suits for the photos 🙂

The biggest surprise to me is no hair nets. I’ve worked on clean rooms, and the air filtration system does a huge amount of the work, but you still wouldn’t want any loose hair ending up under film like that.

I mean, they’re not exactly making pharmaceutical products or semiconductors here; this is not a high-grade cleanroom. Probably ISO 8 at best if it was to be certified (which I doubt it is).

I did say “for the photos” 😛

Should have taken it for a sonic bath first 😉

I look forward to David’s offroad adventures with this machine. The preparation shows that he values it very much and does not want it to get marred when used for its intended purpose.

It’s too bad none of the pictures in the article depicted David’s super-excellent hat. 🙂

(Full disclosure: in summer I wear a range of aggressively dorky (but functional) hats.)

Ahh glad to see it being trailered, the old David is still here

Vinyl Cutting Machine Vinyl Cutters © 2024 The Autopian. All Rights Reserved. Design by Jazel.