For full functionality of this site it is necessary to enable JavaScript. Here are the instructions how to enable JavaScript in your web browser.

Save to read list Published by Will Owen, Editor Global Mining Review, Tuesday, 16 May 2023 08:00 Fragmentation Analysis

Coal mining companies have long been chomping at the bit to accelerate intelligent digital transformation to achieve green mining and high-quality development. The main challenge of digitalisation facing the mining industry is to unify systems and industry standards. There are thousands of different devices at work in each and every mine, generating huge quantities of data – with more being captured with each new development in sensors and monitoring. Systems from different vendors have their own data systems and business logic, making it difficult for them to collaborate. Moreover, there are few universal standards or regulatory systems in-place across the coal mining industry, which are needed for it to innovate towards intelligent mining in the future.

The best way to illustrate the world’s need for intelligent mines and the benefits they can unlock is to use a case study of a country heavily involved in the mining industry.

China is a big producer and consumer of minerals and has an important influence on the global mining market. Indeed, the Chinese mining industry comprises 7% of the country’s GDP. As China is typically considered ‘rich in coal, poor in oil, and short of gas’, coal naturally remains the mainstay in its energy mix. The country currently operates 4300 coal mines and 37 000 non-coal mines. Unlike other major coal producers – such as the US, India, Australia, and Indonesia – where over 60% of yield comes from open-pit mines, only approximately 11% of coal in China is produced this way, due to the scarcity of such deposits. Instead, the majority of mining operations active in the country are located underground, despite being fraught with safety hazards; such as gas leaks, flooding, fire, rock bursts, and coal dust.

With coal representing a large share in China’s economy, making coal mines smarter is one of the keys to upgrading the country’s traditional industries. In March 2020, eight ministries and commissions, including the National Development and Reform Commission (NDRC), the National Energy Administration (NEA), and the Ministry of Industry and Information Technology (MIIT) jointly issued the ‘Guiding Opinions on Accelerating the Development of Intelligent Coal Mines’. According to the document, smart mining shall be the core technology for the future high-quality development of the coal industry. Next-generation information technologies will not only make mines smarter, but will make operations safer and boost quality, productivity, and efficiency.

After many years of development, solutions to aid the digital transformation of the mining industry were found. In the past, all the collected data had been stored in a scattered fashion across different systems. However, now utilising industrial internet architecture, information is stored in one data lake, breaking down the walls of traditional information siloes. Data from various systems can be displayed to support collaboration and control. This enables personnel to simply log in, via a computer or a mobile phone, and monitor the entire working face remotely. This makes it is much easier and simpler for work to be done. In summary, messy and complex data is cleaned and turned into useful data, for the informatisation, digitalisation, and intelligence of mining companies.

Figure 1 – A miner checking the environmental information on his phone at the Xiaobaodang Coal Mine.

Since 2020, the number of intelligent coal mining faces in China has gone up from 494 to 1019, the number of intelligent mines from 242 to 572, and production capacity from 850 million t to 1.94 billion t. The positive impact of these changes has been clear. Indeed, the number of underground workers has dropped significantly, leading to significant improvements in labour efficiency and safety levels. For example, one mine reported that, in the past, at least 13 people were required per shift, due to inefficiency. Now, only five people are required and the operation produces 50% more coal per shift.

The intelligent mine solution powered by 5G and the industrial internet that was jointly developed by Huawei Mine BU and Shaanxi Coal Industry Co., Ltd, celebrated its one-year anniversary in April 2023, marking a full year of continuous operations. The solution has leveraged technologies such as 5G, cloud computing and AI, as well as related digital applications, in order to significantly improve production efficiency and operational safety – it has integrated ICT technologies into every step of the coal mining process to eliminate silos and enable data sharing. This action has supported intelligent collaboration between safety assurance, production, operation, energy conservation, environmental protection and other systems, and has improved efficiency during geological exploration, tunnelling, mining, and more. The solution is the first of its kind to use an industrial internet platform with a three-level architecture of the Shaanxi Coal, its mine subsidiaries, and the coal mines themselves. This platform has enabled collaborative management and control, intelligent sensing, and efficient decision making.

The results of this collaboration make a powerful case for intelligent upgrades for the global mining industry, and provides a reference for applying the industrial internet solutions in other industries.

The Shaanxi Coal and Huawei together developed their industrial internet platform with a three-level architecture (corporate headquarters, mine companies’ group, and mines) – the first in the industry. At the time of writing this article, the platform serves eight mine companies and 36 mines.

Based on the three-level architecture, organisations of different levels can collaborate easily by following the data specification standards set by the group. At the corporate headquarters the industrial internet platform carries the unified data asset catalogue, data standards, and lifecycle management of data – from collection to storage, computing, usage, governance, and secure data sharing. The data models and business models are co-developed and shared across all business segments.

At the group headquarter level, data is aggregated through the cloud and data governance platforms to support comprehensive analysis and decision-making of all business sectors and in-depth analysis applications. Mining companies integrate the data, manage its quality, and use the data services.

Finally, at the individual mines the cloud, industrial IoT, and big data technologies are used to collect, converge, govern, and share operational technology (OT), communication technology (CT), and information technology (IT) data.

Huawei has worked with Shaanxi Coal’s Hongliulin Coal Mine and Xiaobaodang Coal Mine to develop new practices and applications that meet the specific requirements of coal production. In this process, Huawei has leveraged the expertise it has built up in 5G, AI, cloud, big data and other technologies, as well as its capability to integrate global resources. This partnership has created a new benchmark of intelligent mines for the industry. In particular, the intelligent mine solution can build virtual mines that act as the digital twins of physical mines underground, generating greater value with the massive amounts of mining data in a safer and more efficient way.

Founded in 2005, the Hongliulin Coal Mine is located in the hinterland of Northern Shaanxi Base. The mine’s approved production capacity of the mine is 18 million tpy. As a result of Shaanxi Coal and Huawei’s collaboration, the mine now has 18% fewer workers working underground. In addition, 97.7% of its mine faces now support intelligent mining, and intelligent management has been made possible for the underground mine face, using 5G video splicing and video calls. More than 2700 sets of equipment at the mine are now interconnected using unified data standards, with 170 million pieces of data streamed to the data lake every day. This data has been used to create over 100 digital models. This data can also be used to inform production and operation decision making, and to develop new digital applications using ‘zero-code’ development tools.

Figure 2 – Control centre at the Hongliulin Coal Mine utilising a Digital twin.

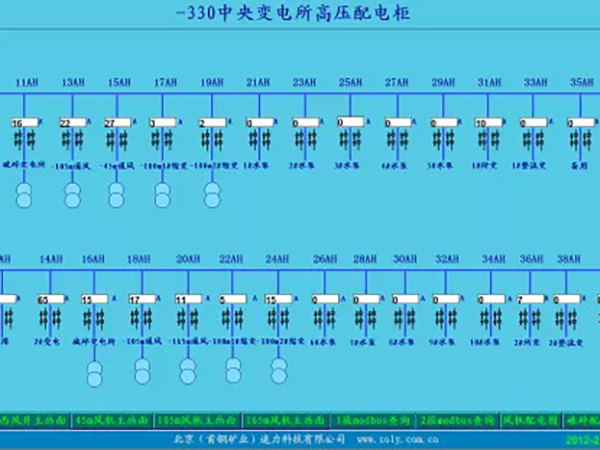

The Xiaobaodang Coal Mine – founded in 2009 and currently operating its No.1 and No. 2 mines with approved capacities of 20 and 13 million tpy, respectively – has also benefitted from Shaanxi Coal and Huawei’s joint efforts. Namely the use of 5G and other technologies to enable intelligent mining processes, equipment and management, significantly improving operational safety and production efficiency. The mine’s underground workforce has been reduced by 42%; and key facilities in the mine, such as the underground water pump rooms and substations, have achieved intelligent, unattended operations, thanks to machine patrol inspection and video-based collaboration. In terms of production safety, environmental monitoring devices installed in the mine are able to autonomously detect and send out warnings related to gas build-up, fires, flooding, ventilation issues and geological events, and enable real-time data interconnection. This can support more informed decision making which greatly improves safety management at the mine.

Figure 3 – Control centre at the Xiaobaodang Coal Mine.

The benefits of digitally transforming mines to enhance their intelligence, through the implementation of ICT technologies, have been made very clear over the course of the past few years: safer mining operations and both higher-quality and more efficient productivity. The results produced by Huawei and Shaanxi Coal’s collaboration stand testament to this.

Looking to the future, the Huawei Mine Team will continue to serve major mining corporations and their subsidiaries across China. It has also begun cooperating with mining enterprises internationally, such as in Asia Pacific and Southern Africa. To further its work in digital transformation, the team is joining forces with industry regulators, ecosystem partners, and scientific research institutes with the aim of advancing the construction of smart mines; making increasing numbers of operations safer, more efficient, and more intelligent.

Read the article online at: https://www.globalminingreview.com/mining/16052023/making-mines-intelligent/

Join our sister publication, World Cement, in Lisbon, 10 – 13 March 2024, for their first in-person conference and exhibition: EnviroTech.

This exclusive knowledge and networking event will bring together cement producers, industry leaders, technical experts, analysts, and other stakeholders to discuss the latest technologies, processes, and policies being deployed at the forefront of the cement industry’s efforts to reduce its environmental footprint.

Get your early bird tickets NOW »

Altilium and New Generation Minerals have partnered on the development of sustainable nickel processing technologies in Western Australia.

Embed article link: (copy the HTML code below):

This article has been tagged under the following:

Chinese mining news Mining equipment news

This content is available to registered readers of our magazine only. Please sign in or register for free.

Register for free » Get started now for absolutely FREE, no credit card required.

Already a member? Sign in here

Cone Crusher Copyright © 2024 Palladian Publications Ltd. All rights reserved | Tel: +44 (0)1252 718 999 | Email: enquiries@globalminingreview.com